Material Requirement Planning is the perfect solution

Material Requirement Planning is a spectacular feature that presents a hierarchy of job orders and suggests an approach to plan and schedule production in a framework. It contains information such as components required for particular job order, quantity required, and quantity available in stock on a single screen. Through this feature, the owner/manager can view the component or quantity and create Purchase Order, Additional Job Order, or Outsource the order with a click.

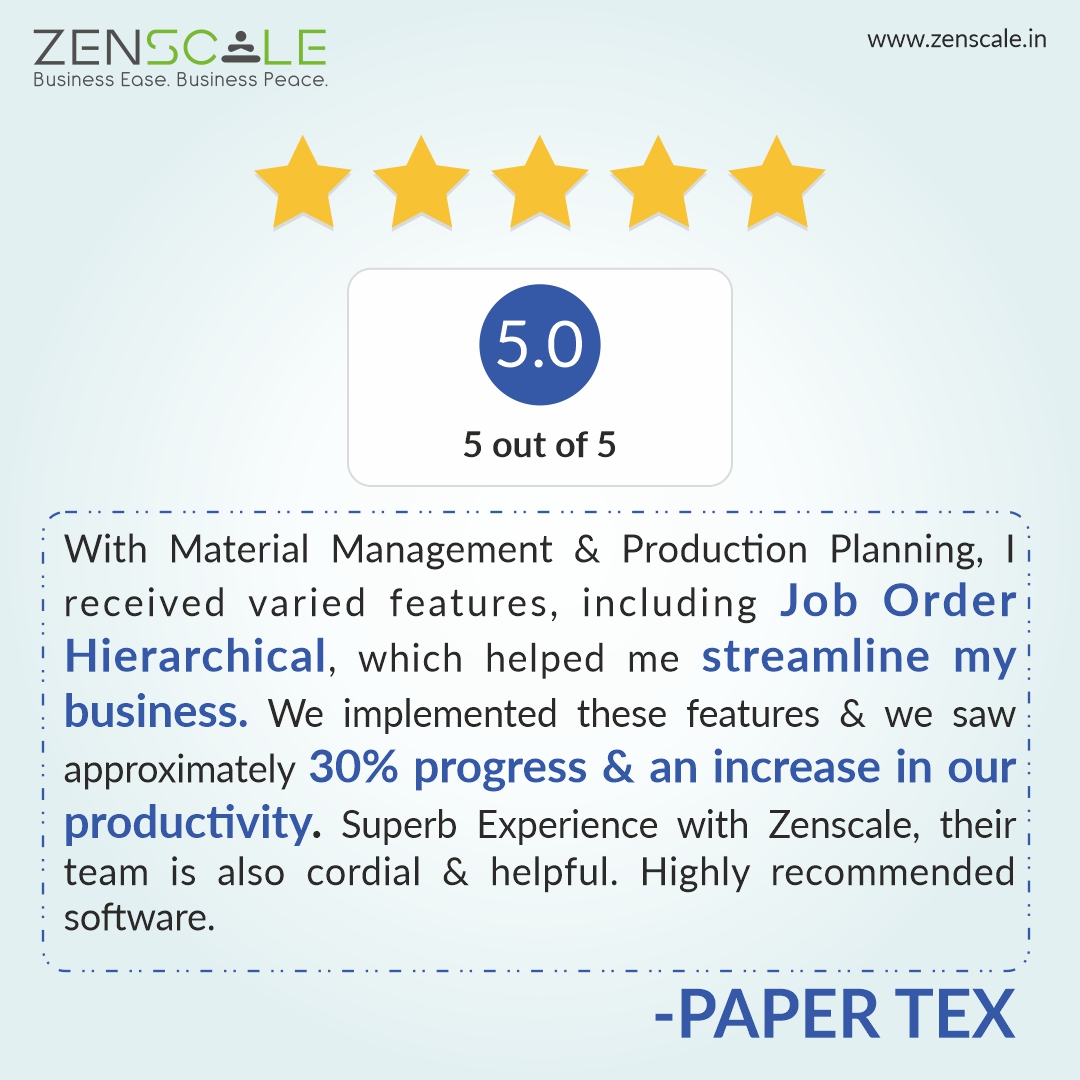

What do companies say about Material Requirement Planning?

Case Study

Papertex Specialty Chemicals Pvt Ltd

Originated in 2014, Papertex Specialty Chemicals Pvt Ltd was started in Punjab with a vision to manufacture and supply quality chemicals for paper and water treatments.

Read MoreBlog

Material Requirement Planning: Control & Schedule your stock in one go

Often business owners complain that they are unable to check the stock levels in their warehouse, which further leads to delay in orders & wastage of inventory. One of our clients, Papertex Specialty Chemicals Pvt Ltd, also shared a similar issue with Zenscale.

Read MoreTestimonial